The Life Cycle of an Oil and Gas Field: Key Stages of Production

10 min read

The lifespan of a , i.e. the period during which the hydrocarbons it contains are extracted, generally varies from 15 to 30 years after production begins. For very large deposits, it can extend to 50 years or more. Deep-sea fields are only exploited for 5 to 10 years due to very high extraction costs.

The hydrocarbon production phase is preceded by several study phases and a construction phase for the facilities, followed by the dismantling of these same facilities and the restoration of the site.

© PASCAL LAURENT - TotalEnergies - AGM-N platform and SETTY drilling rig off the coast of Port Gentil, Gabon

The Preparatory Phase: Studies and Field Development Plan

The exploration phase enabled the quantities and the nature of the hydrocarbons present in the reservoirs to be located and assessed.

Before beginning production itself, oil companies draw up a field development plan:

• they define the production profile, i.e., a simulation that forecasts the production volumes of the deposit (usually oil, gas, and water), year by year, from the start to the end of exploitation, based on estimates of the quantities present in the reservoirs.

• they assess the number of wells required and select the most suitable facilities for the various stages of production (extraction methods, processing of products brought to the surface, temporary storage, shipping).

• they perform economic calculations to determine whether future oil and gas sales will generate the expected return over the life of the operation.

These development studies enable decisions to be made on the of potential new wells, known as “delineation” and “appraisal” wells, which provide additional information on the presence, quantity, nature, and quality of hydrocarbons. The information gathered is used to refine previous studies. These studies are repeated several times until a robust technical and economic development plan is obtained. If this is not the case, the project is abandoned. Development can then move on to the “Project” phase.

Construction of Facilities: Site Preparation and Equipment Installation

, the site must be prepared, leveled, cleared of trees, and roads must be built to transport the necessary equipment. Production facilities, technical premises, and housing for operators must also be built when the site is isolated. , i.e. “at sea”, the production platform must be built, transported, and installed. Drilling must also begin on the first wells that will enable production to start. Once everything is ready and has been thoroughly checked, the field can go into “production.”

Production Phase: Start-up, Plateau, and Decline of The Field

The production cycle of an oil field comprises three phases:

• Start-up (2 to 3 years). During this period, hydrocarbon production increases gradually as “production” or “injection” wells are drilled.

• the “plateau”, during which production is stable. This production plateau generally lasts 2 to 3 years, sometimes longer for large reservoirs; drilling and connecting ‘production’ or “injection” wells continues; enhanced recovery techniques are used (injection of water or gas to maintain reservoir pressure, or polymers to displace hydrocarbons, installation of recovery pumps at the bottom of wells, etc.) to prolong this plateau as much as possible.

• The decline period, during which production falls by 1 to 10% per year. At the end of production, significant quantities of oil and gas nevertheless remain underground. Operators are constantly looking for ways to improve recovery rates from deposits using enhanced recovery techniques. Recovery rates for deposits vary on average from 5 to 50%. The exploitation of gas deposits alone is more efficient because gas is less dense and much more mobile than oil: recovery rates can reach 60 to 80%.

Risks and Uncertainties in Oil and Gas Production

Production is subject to numerous risks. The reservoir may produce more (up to 10 or 20% more oil than estimated) or, conversely, well productivity may be much lower than expected.

There are various reasons for this. From the outset, development is based on uncertainties in estimating hydrocarbon quantities, reservoir characteristics, and production profiles, which engineers strive to reduce and control in development studies and throughout the life of the field. All deposits contain water that rises through the wells along with the hydrocarbons (oil and gas). After a certain amount of time, there is too much water or gas for the facilities to process.

At some sites, the natural gas extracted is not intended for commercialization and must be reinjected into the reservoir. The field may then no longer be economically viable for the oil company.

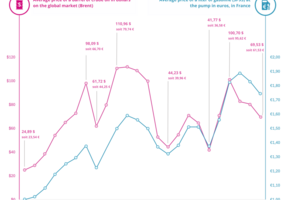

The international economic context also plays a role: if the price of oil falls significantly, some deposits may be abandoned earlier than planned; conversely, if the price rises, deposits may be exploited for longer.

This is why, throughout the life of an oil field, engineers regularly carry out reassessments and optimizations.

When the economic profitability of the field is no longer sufficient, the oil company may decide either to sell the field to another company with different profitability criteria, or to the national company of the host country, or to cease production.

End of Life of the Field: Dismantling and Possible Conversion

When the operator decides to stop field production and in accordance with local and international regulations, the site must be dismantled. This is referred to as “decommissioning.” In general, the facilities are cleaned and dismantled; their equipment and materials are recycled; the wells are plugged and abandoned and the site is restored.

In some cases, the reservoir may be given a second life as a CO2 storage facility.