Refining: From Crude Oil to Petroleum Products

Updated on 01.05.20245 min read

Different types of look different: some are black and viscous, others are brown and fluid. But none of them can be used as is in car engines, boilers or manufacturing units. They first have to be converted into various finished products through refining.

Everyone is familiar with the names of most of these products: gasoline (called petrol in some countries) and are fuels for cars and trucks; jet powers aircraft; , also known as butane and propane, is an automotive fuel or is packaged in bottles and used for household needs; fuel oil is used in domestic and industrial boilers; base oils are used to produce lubricants; and (or bitumen) is used to pave roads. There is also naphtha, which is the main feedstock for petrochemicals.

Refining Operations

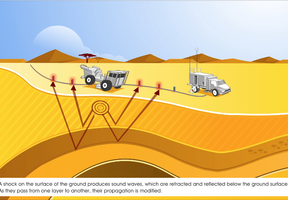

Crude oil is converted into petroleum products in a number of steps in refineries. The first is atmospheric distillation at 350 to 400°C. The crude oil vapors rise inside the column, while the heaviest molecules remain at the bottom. The heavy residues are distilled again in another column.

After separation, the next step is conversion at a temperature of 500°C. Processes include catalytic cracking and , which “crack” the molecules that are still too heavy, producing gas, gasoline and diesel. Then molecules that are corrosive or cause air pollution, such as sulfur, are removed.