Rare Earths

10 min read

John Seaman

The Paradox of Chinese Rare Earths

“Rare earths” have sometimes been referred to as the “oil of the 21stcentury” due to the significant role they now play in the digital and energy industries. The question is whether China, which produces these elements in huge quantities, will be able to harness this “geopolitical weapon”. In this article, John Seaman, a Research Fellow at the French Institute of International Relations (IFRI), provides a thorough analysis of this often controversial issue.

China has a virtual monopoly over the production of the 17 “rare earth” elements, a family of rare metals that are essential in a number of technologies related to the and digital revolution. For some ten years now, industrialized countries have sought to prevent their Chinese partner from taking advantage of this situation. But, paradoxically, the measures taken by these countries have tended to make it more difficult to open new mines outside China.

This surprising situation can be explained if we reexamine the timeline of events and understand the close interdependence of the economic phenomena at play.

- Act I: Rare earths were already used in certain industrial sectors in the 1970s, although to a lesser extent than today, with production mostly confined to the United States, particularly the Mountain Pass mine in California. In the last decade of the 20th century, growing concerns over the environment in California, coupled with accidental pollution at the mine, resulted in stricter legislation that increased production costs. The Mountain Pass mine closed down in 2002, just as global demand was rising.

- Act II: Taking advantage of the abundance of resources underground and a lack of environmental regulations, hundreds of small Chinese operators began mining for rare earths in a chaotic, Wild West-like manner that caused major environmental damage. Supply was easy to ensure and global prices low.

- Act III: In 2006, the Chinese government decided to bring a little order to the situation to guarantee long-term supply to its own booming industries. The authorities also wanted to “move upmarket” in the rare metals industry, so as to be more than merely a commodities producer. In addition, the emerging middle class put pressure on the State to take a more sustainable path to development, with closer attention paid to air, water and soil pollution. In response, the government began setting up a half-dozen structured companies and introduced operating rights, checks, taxes, and production and export quotas, which became binding in 2010. As a result of these measures, prices soared on the international markets.

- Act IV: Industrialized countries, led by Japan and the United States, grew concerned about rising prices and the risk of shortages, which could put some of their industrial sectors in danger. They criticized China for charging higher prices for exports than domestic use and for encouraging offshoring by making international companies come there instead of promoting open international trade. In response, a case was brought against China at the World Trade Organization (WTO), measures to conserve rare earths were encouraged and projects were supported to launch mining operations outside China in Australia, Canada, Kazakhstan, Vietnam and India. Mountain Pass was even reopened in 2012.

- Act V: The international pressure led China to ease its policy of taxes and quotas, which in turn resulted in sharp price drops. This trend turned off investors, who questioned the business sense of committing capital to an industry with low quantities of materials and volatile markets. If prices fell, there would be no guarantee of recovering the significant investment needed in the mining industry. Doubt set in and projects struggled to get off the ground. Following the bankruptcy of its operator, Molycorp, Mountain Pass was sold in 2017 to a of international investors… including Chinese mining giant Shenghe. This same company also invested in a major mining project in Greenland, which has considerable rare earth reserves. The world realized that Chinese quotas actually stimulated production outside the country…

Developments continue to this day. Reserves are still abundant following the discovery by Japan and the United States of vast deposits . However, the market remains small, and if it were flooded with huge amounts of materials, as is typical for mining operations, the prices would discourage producers. Fears of “geopolitical weapons” aside, rare earths are doubtlessly strategically important, but not as essential as oil was and still is today given the sheer magnitude of production and the size of its market.

John Seaman is a specialist in the geopolitics and political economy of energy and natural resources in Asia, with a focus on China and Japan. He has worked at the French Institute of International Relations (IFRI) since 2009. John holds a Master’s degree in international affairs from Sciences Po Paris and a Bachelor of Arts in International Economics from Seattle University in the United States. He has also studied at the Beijing Center for Chinese Studies and was a visiting researcher with the Energy and Environment Program of the Canon Institute for Global Studies (CIGS) in Tokyo.

Gaétan Lefebvre

Using and Recycling Rare Earths

“Rare earths” and other strategic metals are essential components in many energy sectors and in digital technology. Today, however, a number of uncertainties still surround the changing ways in which these elements are produced and used. In this article, Gaétan Lefebvre, a geologist and economist at the French Geological and Mining Research Bureau (BRGM), discusses some of the issues.

The future security of rare earths will depend on a number of factors that are still hard to determine: How will their prices and market availability change? Do they have substitutes in all applications? Can they be recycled on a large scale at a competitive cost? Is it reasonable to invest in facilities when the amount of rare earths needed to facilitate the energy and digital transitions is still poorly assessed and technologies continue to change?

The main factor of uncertainty surrounds recoverable reserves. Since 2010, when China briefly sparked fears of a global shortage amid geopolitical tensions with neighboring Japan, many research studies and projects have shown that potential rare earth deposits are numerous and spread across the entire planet (including on the ocean floor), despite China owning almost half. From a purely geological point of view, the risk of “depletion” is therefore unfounded. Determining a “depletion date” depends on the level of knowledge and technology at a given moment. Since these two factors change with time, the supposed date may never actually arrive. From a geologist’s perspective, then, dedicating more resources to finding rare earths will results in more of the elements being found. However, manufacturers (and politicians) only take into consideration production cost, market prices and industry needs.

The applications of rare earths are an additional factor to take into account. Currently, demand for rare earths is mainly being driven by permanent magnets, which are used to create an extensive range of electric motors in a vast number of areas, from the most strategic (missile guidance systems in the defense sector) to the most common. Even the drum inside your washing machine and your PC’s hard drive contain rare earths.

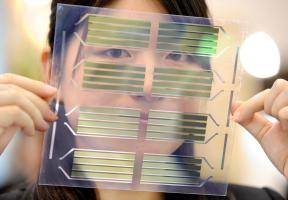

Rare-earth permanent magnets have such a strong magnetic field for such a small amount of material that there is really no other substitute when it comes to manufacturing compact, ultra-high-efficiency electric motors. This is a key factor in certain industries, such as offshore wind , where rare-earth permanent magnets provide the massive wind turbines with high performance and sufficient reliability to reduce the need for maintenance, which is difficult at sea. In other uses, substitutes such as ferrites, electromagnets and copper coils can fulfil the same functions and offer comparable performance, but cannot be miniaturized to the same extent.

The challenge of substitution is therefore to identify and distinguish the essential uses of rare earths from those that are less important. The automotive industry is a good example of this trade-off. Since 2010, carmakers have tried to use rare-earth magnets exclusively for functions where reliability matters most, such as for the steering column and braking systems, and to find substitutes in non-essential uses such as electric window motors, speakers and other auxiliary functions.

Recycling: Japan as a Model

The potential for recycling rare earths is another important issue, although the risk factor in this case is more economic than technological. First, there is the challenge of setting up efficient collection systems in the various industries concerned. Then, a treatment process tailored to increasingly complex products, such as waste electrical and electronic equipment (WEEE), needs to be created to recover the metals of interest. Lastly, the technology needs to be advanced from laboratory testing to industrial-scale rollout, which requires significant – and potentially risky – investment, and a market must be made for the recycled materials.

For example, a recycling facility for end-of-life compact fluorescent lamps was set up in France in 2012. However, the amount of “raw materials” was significantly reduced when the light bulb market shifted massively to LEDs. With the cost of recovering rare earths at the end of the value chain exceeding that of the concentrates available on the market, the recycling facility was forced to close after a few years.

Nevertheless, inspiration can be drawn from Japan’s rare earth recycling model. In 2006, the country’s permanent magnet manufacturers, with support from the government, set up a recycling system similar to that for used bottles and cans, only here for the return of end-of-life products such as vehicles and air conditioners. Carmakers, including Hitachi, Mitsubishi and Honda, conducted research to develop the processes and financed a large portion of the project themselves, fostering the emergence of a sizable secondary source of rare earths.

In France, several research projects on rare earth recycling have been launched, including Extrade at the BRGM, with the goal of developing a pilot metal separator capable of extracting rare earths from waste electrical and electronic equipment. Now that a process has been developed, it is time to rise to the challenge of ensuring industrial-scale roll out and making a market.

Gaétan Lefebvre holds a degree in engineering from École Nationale Supérieure de Géologie de Nancy as well as a degree in natural resource economics from the Toulouse School of Economics. He has worked at the French Geological and Mining Research Bureau (BRGM) since 2014, where he is responsible for business intelligence and mineral analysis in a number of metal markets. Gaétan has notably contributed to Panorama du Marché des Terres Rares, an overview of the rare earth market published in 2015.