Life Cycle Assessments (LCA) Of Plastics

Published on 10.02.202010 min read

A is a method used to evaluate a product’s environmental and energy impact, from its manufacture through to use and end of life. Here, we take a look at the life cycle of plastics.

1. Life Cycle Analysis of Plastics

Often accused, plastics can have a virtuous life cycle if we are careful not to abandon them or dump them anywhere. Production, use, : three phases that allow us to reap the full benefits of materials that are irreplaceable in many sectors.

2. Four Key Steps

Shaping the plastics industry around the circular economy model is vital to ensuring that this material is more sustainably developed. The first step is manufacturing the base materials (pellets, fibers and powders). The second step involves processing these materials into products for day-to-day use as well as housing, automobile and leisure applications. The third step is use. Following this, waste must not be disposed of in natural environments or landfills; as much of it as possible should be sent to the fourth stage: recycling and energy recovery. This can be achieved with technology and the right behavior from the general public and other economic stakeholders.

3. Step 1 – Manufacture of Base Materials

As carbon-based materials, plastics are essentially derived from , and more specifically from naphtha molecules, which are lighter than gasoline. They can also be obtained from sources such as starch or cellulose in cereals including corn. Research is even being conducted to produce plastics from CO2 gas combined with . The petrochemicals and "green" chemistry industries produce polymers that are assembled into various arrangements in pellet, powder or liquid form. This photo shows pellets derived from potatoes that are used to manufacture bags.

4. Step 2 – Processing

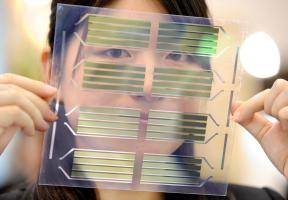

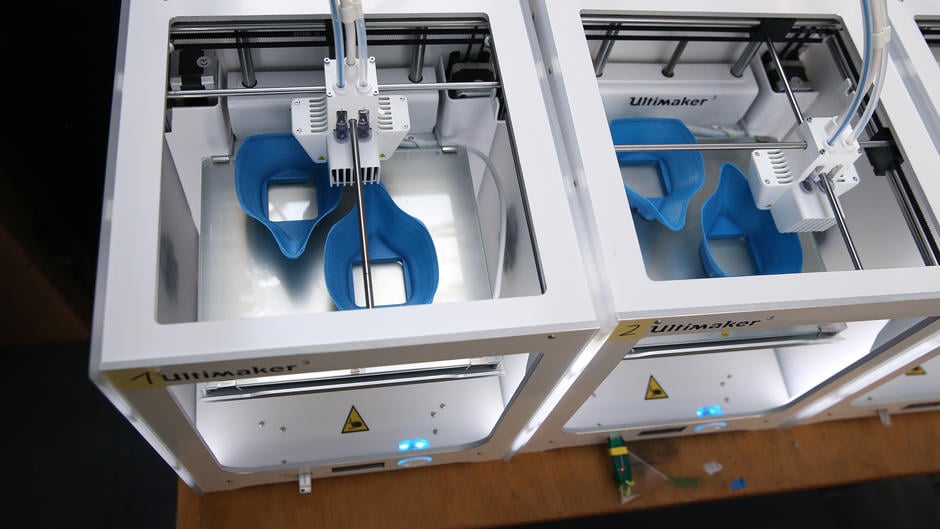

In 2018, 360 million metric tons of plastics were produced worldwide (more than half of which in Asia, and 62 million metric tons in Europe). Polyethylene is used to make food-grade plastic wrap and bags, PVC to make , PET in to make bottles, polypropylene to make kitchen utensils and auto parts, and polycarbonates to make DVDs and helmet visors. All of these products are manufactured in processing plants. The refining and processing stages are extremely energy intensive. This photo, taken in Halle, Germany, shows masks being 3D-printed for emergency rescue crews.

5. Step 3 – Plastic Use

Among plastics' countless applications, packaging is one that has soared in popularity. In Europe, packaging accounts for 40% of demand for plastics, while construction represents 20% and automotive 10%. Plastic packaging is often thrown away after one use but, on average, it cuts the weight of shipments fourfold compared to glass or wood, shrinking transportation-related CO2 emissions as a result. In the food industry, plastic wrap ensures a greater level of hygiene: a steak wrapped in plastic film keeps for ten days longer on the shelf, reducing waste by 75%. This photo shows a Miami supermarket during the COVID-19 pandemic.

6. Repair and Reuse of Products

The useful life of plastic products varies wildly, from just a few hours for a single-use bag, to years for auto parts and even decades for home insulation materials. The energy performance and of a product heavily depends on this useful life. For example, reusing a shopping bag reduces its environmental footprint. Having an everyday appliance repaired instead of replacing it will also have a considerable impact, pushing back against the illegal practice of planned obsolescence at the same time. Shown here is a “repair café” in Bangalore, India.

7. The Unexpected Impact of Fishing Nets

As fishing are made from plastics these days, they are a major cause of marine pollution when lost or dumped. Even when merely torn, nets still strangle sea animals, including large ones such as seals, dolphins and even whales. These so-called "ghost nets" are thought to account for 10% of all marine debris. Companies are now beginning to retrieve and repair them, bringing them back into the life cycle. This photo shows a tugboat off the coast of Reposaari, in western Finland, "fishing for nets" in the Baltic Sea.

8. Dumping: A No Go

There is no worse way to dispose of plastic than leaving it in natural environments, as the majority of this waste finds its way into the oceans. Marine waste has always existed, but today plastics account for over 80% of its total volume. Almost all of this waste is found on the seabed and much of it is microscopic (ranging from 1 millimeter to 1/1000 of a millimeter in diameter) due to the slow decomposition of polymers. It is up to economic stakeholders, local authorities and particularly the general public to resolve this issue. Seen here, young attendees at the Glastonbury music festival, in southwest England, clean up the site after the event.

9. Landfills: A Dead-End

Storing and burying waste admittedly can prevent it from contaminating natural environments. However, this is not a long-term solution given the exponential increase in waste, not to mention the soil pollution it can cause. In Europe, Switzerland, Germany and the Scandinavian and Benelux countries have practically rendered this practice obsolete, while the United Kingdom, France, Italy and Spain still have landfill rates of between 20% and 40%. What is more, the most developed countries export their waste to less well-off ones – albeit less and less. In this photo, an Indonesian customs officer keeps watch over containers of waste illegally shipped to Batam.

10. Step 4: Recycling

The best solution is to recycle used plastics to bring them back into the life cycle. The most prevalent method used today is mechanical recycling, a process that converts waste into reusable material, without altering its chemical structure. In theory, all types of thermoplastics, i.e., those that soften under and then harden when cool, can be mechanically recycled with no loss of quality. Recycling is naturally beneficial from an environmental perspective, but here again the entire cycle needs to be considered, including waste collection, sorting and transportation.

11. Chemical Recycling

A method still relatively undeveloped, chemical recycling alters the molecular structure of plastic waste to feed it back into the initial stages of the cycle, i.e., at the base material manufacture phase. The plastics are “depolymerized” so that complex molecules can be reassembled. Plastic waste can also be used in blast furnaces where, converted into synthesis gas, it can act as a substitute to , and natural gas to extract pure metals from iron ore and other metal oxides.

12. Energy Recovery

Some waste cannot be recycled as it is unsorted or not sufficiently homogeneous. In these cases, it can be incinerated in facilities that often can produce a combination of heat and . Modern incinerators are fitted with technology that reduces their gas and particulate emissions, and the heat generated can supply district heating networks or plants with high energy needs, such as cement factories. Pictured here is a state-of-the-art facility in Fos, in the south of France, that uses a combination of processes: , mechanical recycling and digestion of organic waste.

Our most popular content

Our most popular content

See all