Offshore Oil and Gas Production

5 min read

and gas production, which involves extracting oil and gas from beneath the sea, is a critical component of the world's energy supply. It requires the use of increasingly sophisticated technology and ever greater attention to the related environmental impacts.

© SORDOILLET PATRICK - TotalEnergies - The PARAGON L1115 located some 100 km off the shore of Qatar.

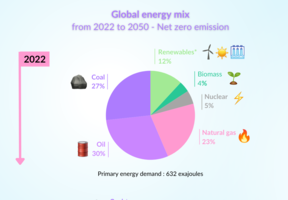

production accounts for 30% of global oil production and 27% of global gas production. These percentages have remained stable since the early 2000s and are unlikely to change any time soon, despite the rapid development of unconventional resources such as and and gas. Offshore production currently accounts for an estimated 20% of the world's oil reserves and 30% of global gas reserves.

Cost and environmental constraints

As with unconventional resources, the main constraints for offshore production concern cost and the environment. Despite technological advances, each stage of the oil and gas production process – from exploration, and extraction to the construction of purpose-built platforms and vessels – requires billions of dollars in investment. Each project’s cost competitiveness has to be assessed on a case-by-case basis.

Concerning the environment, accidents like the April 2010 Macondo blowout in the Gulf of Mexico have led companies to systematically revise their existing facilities, change the way their seabed installations are designed and reinforce their best practices. Given the scope of such disasters, their effect on a company’s image and their financial impact, constant vigilance is required, especially when working in such fragile environments as the Arctic.

The rise of deep offshore production

Offshore production began in the 1950s in shallow waters around 200 meters deep. Platforms were erected on the seabed, supported by metal or concrete legs. Following the 1973 oil crisis, intensive production began in the North Sea. Half of the 17,000 platforms in use today are fixed structures anchored to the seabed.

In the 1990s, companies began to go deeper, reaching depths of between 400 and 1,500 meters (deepwater), or more (ultra-deepwater). Companies now produce oil from depths of up to 3,000 meters, and are currently setting their sights on the 4,000-meter mark. Of course, several thousand meters of sediment must be drilled through to access resources located at such depths.

Deepwater production is moving farther and farther offshore. For example, the Libra offshore oil field development, located more than 200 km south of Rio de Janeiro, is targeting reservoirs beneath a salt layer, some 3,500 meters under the seabed ,which itself is under 2,000 meters of water.

Deep offshore production has expanded rapidly in recent years, from 3% of global production in 2008 to 6% today.

Underwater factories

Deep offshore production can pose a number of challenges1:

Instead of fixed platforms, which are connected to wellheads via rigid tubes, deep offshore production requires floating facilities connected to the wells using flexible risers. Some risers are used to inject the water and gas that pushes the oil towards the production wells, while others transport the oil to the surface. The risers are encased in insulating sleeves to prevent the oil – which is extracted at more than 50°C – from cooling too quickly in the deepwater conditions and the paraffin from obstructing the pipes. More and more operations, such as separating oil from gas, are being performed under the sea, turning these installations into a sort of underwater factory.

A network of pipelines installed by specialized vessels and underwater robots can be used to bring the oil onshore. However, if the oil field is situated too far off the coast and more than 1,000 meters deep, a barge or a is generally used to produce, store and offload the oil. These vessels, known as Floating, Production, Storage and Offloading units, or FPSOs, can hold up to 2.5 million barrels of oil. A single field may have several FPSOs, which can remain in place for 20 to25 years.

In order to concentrate all operations as close to the production site as possible, facilities are also under consideration, opening up the possibility of liquefying gas immediately after production. This solution would eliminate the need to build costly onshore gas pipelines and plants, which always generate debate due to their environmental impacts.

Sources: