Energy Management on an Anaerobic Digestion Farm

Published on 05.20.20195 min read

In 2010, in Moustoir Remugnol, France, was the first pig farm in Brittany to produce from manure and plant matter. So far in 2019, it has produced ten times more energy – and – than it consumed and it aims to increase this amount to between 40 and 50 times by 2021. The owner, Jean-Marc Onno, explained the advantages and disadvantages of agricultural digestion to Planète Énergies.

© J.M ONNO - A "post-digester" on Jean-Marc Onno's farm, where the last phase of organic matter fermentation takes place.

Organic Matter Used

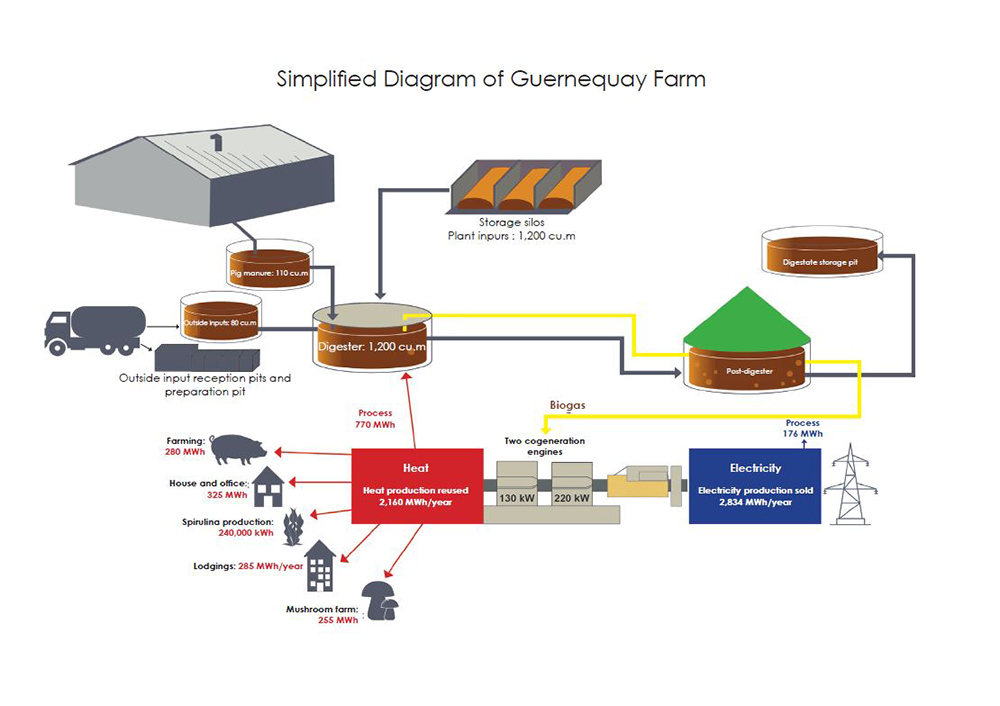

Three types of input produce biogas through on Jean-Marc’s farm:

Manure

Also known as slurry, manure is made from waste produced by around 3,500 pigs and piglets on the farm. Some 6,300 cubic meters is collected per year (almost 18 cubic meters per day).

Plants

Agricultural and plant waste from intermediate energy crops are collected from several surrounding farms. These crops (rye, sunflower and oats) are harvested between two main crops – wheat and corn in this case – ensuring that the ground is covered in plant matter during the full farming cycle. Almost 3,500 metric tons are stored per year in silos (silaging). Note that “silo juice” is added to the manure.

Food Processing Byproducts

This input comprises fat from the abattoir used for the pigs from Guernequay farm and oils from other sites within a radius of 10 kilometers. Each year, 4,300 cubic meters of these products are used.

Together, these three inputs amount to 13,800 metric tons per year. Manure makes up just under half of the total. It is a weak methanogen, only contributing 7% to biogas production. The intermediate energy crop silage and food processing byproducts make up the other half. While they are much more effective, manure is needed for biological stability.

The inputs, which are mixed into a liquid, are poured into the 1,200-cubic‑meter digester at regular intervals. The digester is made up of a 6-meter‑deep pit whose visible section is covered by a concrete roof.

Jean-Marc Onno, pig farmer, manages one of the largest methanisation farms in Brittany. ©J-M Onno

This mix must stay in the digester and a second post‑digester for 45 to 50 days at 40°C for the organic carbon to transform into gas through anaerobic fermentation (away from oxygen). Each year, the unit produces more than 1,250,000 cubic meters of biogas made up of 60% methane (natural gas) and 40% carbon dioxide. A is left at the bottom of the digesters which is stored and then used as fertilizer on the surrounding fields. Annually, 13,700 cubic meters of digestate fertilizes 340 hectares of crops, avoiding the need for chemical fertilizers.

Heat and Electricity Production

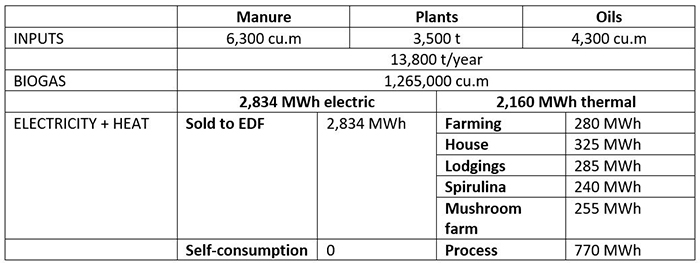

The gas is used to two engines of 130 and 220 kilowatts, making Guernequay farm a leader in the agricultural anaerobic digestion sector in France. The engines are three to four meters long and produce electricity via a turbo generator. This process produces heat, which is recovered to heat a water system.

The heat supplies the whole farm via a two‑kilometer pipe system. It is used to heat the digester, the livestock enclosures, the house and some lodgings in the outbuildings. It also supplies two production units on the site: a mushroom farm set up with outside partners that has 20 employees, and a small factory that makes spirulina – a food supplement requiring water heated to 37°C.

The electricity is mainly sold to the grid. Enough electricity is produced to power the equivalent of 500 homes. Photovoltaic panels on the roof provide extra electricity, which is also sold to the grid. A small amount is consumed on the farm to run the machinery.

The following table breaks down the different uses:

Profitability

Revenue from electricity sales throughout the year comes to €575,000. EDF, the French electric utility, buys the electricity at a feed-in tariff of €0.215 per kilowatt-hour. This is much higher than the price for photovoltaic kilowatt-hours, because it is eligible for a “livestock waste” subsidy that rewards the environmental aspect (waste treatment, local ecosystem development, etc.). Furthermore, the heat is reused elsewhere (mushroom farm) reducing the electricity bills of the house and farm.

However, the system requires a great deal of maintenance: three to four hours of work every day with around-the-clock standby, i.e., a full-time job (€40,000). Engine maintenance is estimated at €75,000 a year once the system is up and running. It has a perverse side effect: for some 250 hours every year, electricity production is shut down and any gas produced during this period must be flared. Maintenance of digesters, production of intermediate energy crops, insurance and biological analyses add another €115,000 to the bill. A total of 175,000 kilowatt-hours of electricity is consumed per year, coming to around €20,000.

The profit made paid off the upfront investment of around €1,700,000 (including €280,000 in subsidies) over seven years. A major drawback is that approximately half of the upfront investment must be reinvested within ten years to replace the engines and other machinery.

Future Prospects

The methane could also be fed into the public network. The entry point is only six kilometers away, meaning that gas can be connected by a pipeline instead of transporting it in tank trucks. However, the tariffs governing the initial cogeneration system are not high enough for Guernequay farm to make a profit.